A home inspector’s discovery of knob-n-tube wiring in St. Joseph homes, with replacement costs, insurance impacts, and safety risks.

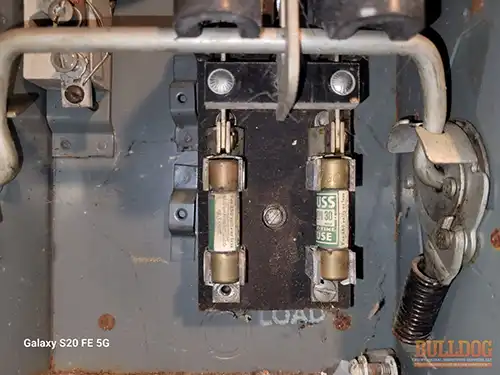

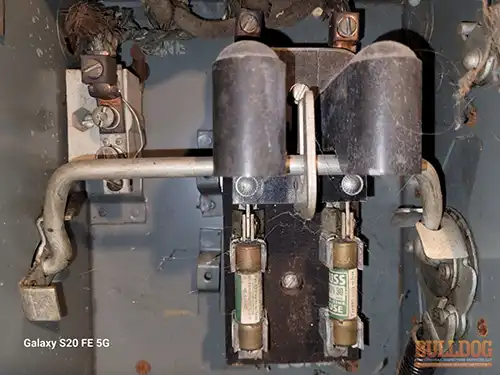

During the electrical inspection of a vacant 105-year-old bungalow in the Brookdale Addition subdivision of St. Joseph, MO. Wednesday morning, I found live knob-n-tube wiring running through the attic and walls.

The cloth insulation on the conductors had become brittle and was cracking in multiple locations, exposing bare copper wire.

When I tested the circuits, they were active and carrying current.

The ceramic knobs and porcelain tubes were intact, but the rubber-coated wiring they supported had deteriorated to the point where even gentle handling caused the insulation to flake off in pieces.

This wasn’t a historical curiosity preserved behind walls. This was an active electrical system powering lights, outlets, and appliances throughout the home.

Knob-n-tube wiring lacks the grounding conductor that protects modern electrical systems from faults and surges.

The system uses only two wires, hot and neutral, which means any electrical fault has no safe path to ground. In St. Joseph’s housing stock built between 1880 and 1940, I find active knob-n-tube wiring in approximately 15% of homes over 100 years old.

The insulation deteriorates predictably after decades of heat cycles, and modern electrical loads routinely exceed the 10-15 amp capacity these circuits were designed to handle.

This creates immediate safety concerns.

Fire hazards develop when cloth insulation exposes live conductors or when building insulation traps heat around wiring designed to dissipate heat into open air. Insurance companies recognize these risks, which is why many refuse coverage or require complete replacement before issuing policies on homes with active knob-n-tube systems.

Understanding Knob-n-tube Wiring: What It Is and Why It Fails

What Is Knob-n-tube Wiring?

Knob-n-tube wiring is an electrical system that uses individual insulated copper conductors supported by ceramic knobs and protected through wood framing by porcelain tubes. The system was standard in North American construction from approximately 1880 through the 1940s, when it was gradually replaced by modern cable systems that bundled conductors together.

The name describes the installation method. Ceramic knobs mounted to floor joists and wall studs hold the wires in place, keeping them separated from combustible wood materials. Porcelain tubes protect the conductors as they pass through framing members. The wiring itself consists of cloth-wrapped or rubber-insulated copper wire, with hot and neutral conductors running separately through the structure rather than bundled together in a protective sheath.

This open-air design allowed heat from electrical current to dissipate naturally into surrounding space, which was essential given the insulation materials and conductor sizes used at the time. The system worked well for the low electrical demands of early 20th century homes, typically handling 10-15 amps per circuit for basic lighting and minimal appliance use.

Why Knob-n-tube Wiring Fails

Knob-n-tube wiring fails because its design cannot accommodate modern electrical demands or building practices. The cloth and rubber insulation breaks down after decades of exposure to heat cycles, becoming brittle and cracking to expose bare copper conductors. This deterioration accelerates in attics where summer temperatures routinely exceed 120 degrees Fahrenheit.

The system lacks a grounding conductor, which modern electrical codes require for safety. When an electrical fault occurs in an ungrounded system, there’s no designated path for excess current to flow safely to earth. This increases shock risk and creates fire hazards when fault current seeks alternate paths through building materials or plumbing systems.

Modern electrical loads overwhelm circuits designed for 10-15 amps. St. Joseph homes built in the 1920s typically had six to eight circuits total serving the entire house. Today’s homes require 20-40 circuits handling 15-20 amps each, plus dedicated 30-50 amp circuits for major appliances. When homeowners plug modern devices into knob-n-tube circuits, they routinely exceed the system’s capacity, causing overheating and accelerated insulation failure.

How the System Develops Problems Over Time

The progression from functional to hazardous happens gradually. Year one through twenty, the system operates as designed with minimal issues. The insulation remains flexible, and electrical loads stay within original design parameters.

Years twenty through fifty mark the transition period. Insulation begins stiffening as plasticizers in rubber compounds evaporate and cloth fibers dry out. Homeowners add electrical devices the system wasn’t designed to handle. Someone extends circuits or makes modifications without understanding the system’s limitations.

After fifty years, failure becomes likely. The insulation cracks when wires are moved or disturbed. Building renovations add insulation that covers knob-n-tube wiring, trapping heat and accelerating deterioration. Multiple amateur modifications create dangerous conditions throughout the system. At this stage, the wiring presents active fire and shock hazards rather than just being obsolete.

Here are the most common questions homebuyers ask about knob-n-tube wiring:

How much does it cost to replace knob-n-tube wiring?

Replacing knob-n-tube wiring costs between $8,000 and $15,000 for most homes in the St. Joseph area. The final price depends on your home’s size, the accessibility of existing wiring, the number of circuits requiring replacement, and whether your electrical panel needs upgrading to handle modern loads.

Cost Breakdown

The total expense includes five primary components:

- Labor costs: Electricians charge $75-125 per hour in the St. Joseph area, and complete rewiring usually requires 80-200 labor hours in the average 2,000 square foot home

- Materials: New wiring, boxes, outlets, switches, and circuit breakers add $2,000-4,000 to the project

- Electrical panel upgrade: Replacing an old fuse box with a modern 200-amp service panel adds $1,500-3,000

- Drywall repair: Opening walls to access wiring and patching afterwards costs $1,000-2,500 depending on how many walls require work

- Permits and inspections: Local building department fees range from $200-500

Accessibility drives the biggest cost variations. Homes with unfinished basements and accessible attics cost less to rewire because electricians can run new circuits without extensive wall opening. Two-story homes with finished spaces throughout require more invasive work, pushing costs toward the upper end of the range.

St. Joseph’s older housing stock includes many balloon-framed homes where wall cavities run uninterrupted from basement to attic. This construction style actually makes rewiring easier because electricians can fish wires through full-height wall spaces without cutting multiple access holes at each floor level.

Partial replacement is possible but rarely recommended. If knob-n-tube circuits serve only your attic or basement, you might replace just those sections for $3,000-5,000. However, insurance companies and mortgage lenders typically require documentation that the entire system has been replaced, not just the accessible portions.

The investment adds value when selling. St. Joseph homebuyers expect updated electrical systems in century-old homes, and active knob-n-tube wiring often kills deals or triggers significant price reductions during negotiations.

How can you tell if your home has knob-n-tube wiring?

You can identify knob-n-tube wiring by looking for these visual features in your attic, basement, or crawlspace:

- Individual black and white wires running separately (not bundled together in a cable)

- Porcelain knobs mounted to joists with wires wrapped around them

- Ceramic tubes protecting wires as they pass through wood framing

- Cloth or rubber insulation covering copper conductors

The wiring is most visible in unfinished spaces. Check your attic near where the roof meets the exterior walls, look along floor joists in basements or crawlspaces, and examine areas around old light fixtures or outlets. The ceramic knobs are white or brown and roughly two inches in diameter. Wires wrap around them in a figure-eight pattern, held in place by the knob’s ridged design.

Porcelain tubes appear where wires pass through structural members. They’re cylindrical, typically four to six inches long, and protect conductors from contact with wood as they penetrate joists or studs. You’ll find them at regular intervals where wiring changes direction or passes between floors.

The insulation itself provides clues. Early knob-n-tube used cloth woven around the conductor, often with a rubberized coating. Later installations used solid rubber insulation. Both types feel different from modern plastic-sheathed cable. The cloth version has a woven texture, and the rubber version feels more brittle than flexible after decades of aging.

Not all old wiring is knob-n-tube. St. Joseph homes from the 1930s and 1940s sometimes have early cable systems where two conductors are bundled in cloth sheathing but still lack grounding. If you see bundled wires rather than individual separate conductors, you may have early Romex or armored cable instead.

If you’re uncertain after visual inspection, hire a licensed electrician to examine your electrical system. They can trace circuits, test for grounding, and document which portions of your home still rely on knob-n-tube wiring versus updated systems.

Does knob-n-tube wiring need to be replaced?

Knob-n-tube wiring should be replaced when any of these conditions exist:

- The cloth or rubber insulation has deteriorated, exposing bare copper wires

- Building insulation covers the wiring (creating fire hazards from heat buildup)

- Circuits are overloaded with modern electrical demands

- You’re planning major renovations or electrical upgrades

- Your insurance company requires replacement as a condition of coverage

Complete replacement isn’t legally required in most jurisdictions. St. Joseph and surrounding areas don’t have ordinances mandating removal of existing knob-n-tube systems. The wiring is grandfathered under older electrical codes as long as it remains unmodified and in its original configuration.

However, practical realities often force replacement. Insurance companies increasingly refuse coverage or charge prohibitive premiums for homes with active knob-n-tube wiring. Mortgage lenders may decline financing or require replacement before closing. Real estate transactions stall when buyers discover the system during inspections.

The decision becomes urgent when renovations trigger permit requirements. Adding insulation to an attic with knob-n-tube wiring, finishing a basement, or making electrical modifications all require bringing affected circuits up to current code. At that point, you’re better off replacing the entire system rather than working around grandfathered wiring.

Safety concerns should drive the timeline. If insulation is deteriorating, circuits are overloaded, or you’re experiencing frequent blown fuses, replacement becomes necessary regardless of insurance or lending requirements. Waiting for a fire or electrical shock to force the issue puts your family and property at unnecessary risk.

The best approach treats replacement as a planned upgrade rather than an emergency repair. Budget for the work, get multiple quotes from licensed electricians, and schedule it during a renovation when walls are already open. This strategy minimizes costs and disruption while eliminating a significant liability from your home.

Why is knob-n-tube wiring dangerous?

Knob-n-tube wiring creates five primary hazards:

- No grounding wire means no protection against electrical faults or surges

- Aging insulation becomes brittle and cracks, exposing live conductors

- Modern electrical loads exceed the system’s 10-15 amp capacity per circuit

- Building insulation traps heat around conductors designed to dissipate warmth into open air

- Improper modifications by untrained individuals create hidden dangers throughout the electrical system

The lack of grounding creates the most serious safety deficit. Modern electrical systems include a third conductor that provides a dedicated path to earth for fault current. When a hot wire contacts a metal appliance case or a tool develops an internal short, the grounding conductor carries excess current safely away, tripping the circuit breaker and preventing shock or fire.

Knob-n-tube systems have no such protection. Fault current seeks any available path to ground, which could be through building materials, plumbing systems, or a person touching the affected appliance. This dramatically increases electrocution risk and creates fire hazards when current flows through unintended paths.

Insulation degradation compounds these dangers. The cloth and rubber materials used in knob-n-tube construction weren’t designed for the heat exposure they’ve experienced over decades of service. When the insulation cracks and falls away, bare copper conductors remain energized inside walls and attics. Any contact with metal framing, plumbing, or wood can create shorts that cause fires without tripping overcurrent protection.

When building insulation covers knob-n-tube wiring, it traps heat around conductors designed to dissipate warmth into open air. This heat buildup accelerates insulation deterioration and creates fire hazards. The National Electrical Code forbids insulation from covering knob-n-tube wiring specifically because of this risk. In St. Joseph homes built before 1950, attic insulation added during energy efficiency upgrades often buries knob-n-tube circuits without the homeowner’s knowledge.

Circuit overloading represents a chronic rather than acute danger. The system was designed when homes used electricity primarily for lighting and perhaps a radio or iron. Modern homes run refrigerators, computers, televisions, microwaves, and dozens of other devices simultaneously. Each additional load generates heat in the conductors, and when you exceed the circuit’s capacity, you’re operating the system in a continuous failure mode that will eventually cause a fire.

Can you get homeowners insurance with knob-n-tube wiring?

Many insurance companies either refuse coverage or charge higher premiums for homes with active knob-n-tube wiring. Some insurers will provide coverage under these conditions:

- A licensed electrician inspects the system and certifies it’s safe

- The wiring is scheduled for replacement within 30-60 days of closing

- Only specific circuits remain active (not serving entire home)

- The homeowner agrees to higher deductibles or premiums

- The system is limited to uninsulated areas like basements

The insurance industry views knob-n-tube wiring as a fire risk based on decades of claims data.

Companies that do offer coverage typically impose restrictions that make keeping the system impractical. You might face premiums 50-100% higher than standard rates, deductibles of $5,000-10,000 instead of $1,000-2,500, and policy exclusions that deny fire claims if knob-n-tube wiring contributed to the loss.

Finding coverage requires shopping multiple carriers.

Regional insurers familiar with St. Joseph’s older housing stock may be more flexible than national companies using standardized underwriting rules. Some specialize in historic homes and understand that well-maintained knob-n-tube systems in limited applications pose manageable risks.

The electrician certification route provides the most viable path to coverage without immediate replacement. An inspector examines your system, tests circuits for overloading, verifies that no insulation covers the wiring, and documents that all connections are proper and secure. If the system passes, they provide a written certification that you submit with your insurance application.

This certification typically remains valid for one year, after which insurers may require re-inspection. The process costs $200-400 but can make the difference between securing coverage and being forced to replace the system before closing on a home purchase.

Long-term, however, replacement remains the most practical solution.

Insurance requirements tighten over time, premiums for knob-n-tube homes continue rising, and the difficulty finding coverage increases as more companies exit the market for older homes. Planning for replacement within 2-3 years of purchase eliminates these ongoing complications and improves your home’s value and safety.

Conclusion

Knob-n-tube wiring in older homes in St. Joseph and other areas around Kansas City isn’t an isolated problem. It’s a predictable issue in housing stock built during the system’s 60-year dominance of residential electrical installations.

Understanding the safety concerns, replacement costs, and insurance implications helps homebuyers make informed decisions rather than discovering these issues during contingency periods when time pressure forces hasty choices.

Proactive replacement costs $8,000-15,000 in the St. Joseph area, while emergency repairs following electrical fires or failed insurance applications cost substantially more in property damage, temporary housing, and crisis-driven contractor premiums.

Budget appropriately, hire licensed electricians for proper installation, and document everything for future buyers who will appreciate the peace of mind that comes with a modernized electrical system.

About the Author

Steve Rodriguez is a professional home inspector and the owner of Bulldog Professional Inspection Services. He performs more than 600 home inspections annually all across the KC metro area.

Based in: Raymore, MO

Service Areas: Belton, Raymore, Harrisonville, Grandview, Lee’s Summit, Blue Springs, Raytown, Independence, Liberty, Kansas City, MO, Kansas City, KS, Olathe, Leawood, Overland Park, Prairie Village, Shawnee, Lenexa

Certifications: Certified Master Inspector® (CMI). International Association of Certified Home Inspectors (InterNACHI) Certified Professional Inspector since 2004.

This article is based on a real inspection conducted in December 2025. The property address has been excluded for privacy. Cost estimates reflect Kansas City metro area pricing as of December 2025 and may vary based on specific conditions and contractor selection.

Helpful Links

- [Check out our GBP post about this lesson](GBP lesson post URL – leave as placeholder)

- Recent inspections around St. Joseph, MO

- Home inspection lessons found around St. Joseph, MO

- Learn more about St. Joseph electrical types

Schedule Your Home Inspection

Call: (816) 564-3081

Email: info@bulldoginspect.com

Schedule Your Inspection Online