A home inspector’s feedback of missing chimney liner in Grandview gas furnace installation, with safety risks and liner installation costs

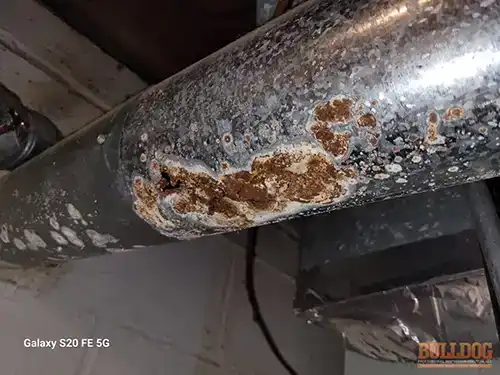

I showed up Monday afternoon to inspect a vacant 70-year-old ranch in the Stomp’s John M subdivision of Grandview. The home had been sitting empty, and once I made my way to the basement to check the HVAC system, I found the gas furnace venting directly into an unlined clay chimney flue.

This is one of those findings that’s easy to miss if you don’t know what to look for.

That’s because venting a gas appliance into an unlined chimney can create a slow, invisible deterioration process that impacts both the chimney structure and indoor air quality.

Modern gas furnaces produce cooler, moisture-laden exhaust compared to older heating systems.

When these combustion gases enter an unlined masonry chimney, the temperature difference can cause condensation. This acidic condensate can attack the mortar joints and clay materials from the inside out, weakening the chimney’s structural integrity over time.

The issue compounds in Grandview’s climate, where winter temperatures drop low enough to keep clay flues cold. Cold chimney walls can reach dewpoint faster, producing more condensation per heating cycle. Over months and years, this moisture damage can create cracks that allow carbon monoxide and other combustion gases to leak into living spaces.

Unlined chimneys were common in Grandview homes built 50-100 years ago because older furnaces ran hotter and drier.

Those high exhaust temperatures kept moisture in vapor form until it escaped outdoors. Today’s more efficient furnaces save energy by extracting more heat, but that means cooler, wetter exhaust that needs proper liner protection.

Understanding Gas Furnace Venting Into Unlined Chimneys: What It Is and Why It Fails

What Is an Unlined Chimney?

An unlined chimney is a masonry structure built with bare brick or clay and mortar joints, lacking the protective metal that safely channels combustion gases outdoors. These chimneys form a hollow vertical shaft from the basement through the roof, and when a gas furnace vents into this open cavity, exhaust gases contact every brick, mortar joint, and masonry surface along the entire path.

The metal liner serves as a dedicated pathway sized specifically for the furnace’s exhaust volume. Without it, exhaust gases interact directly with porous masonry materials that absorb moisture and allow gases to permeate through deteriorating mortar joints.

Why Venting Into Unlined Chimneys Fails

Modern gas furnaces with 80% efficiency ratings produce exhaust temperatures around 300-400°F.

While this seems hot, it’s cool enough to reach dewpoint when contacting cold chimney walls.

The condensation that forms can contain sulfuric and carbonic acids from the combustion process.

These acids can dissolve the calcium carbonate in mortar joints and gradually eat away at brick and clay materials. The rough interior surface of unlined chimneys disrupts smooth airflow, reducing draft efficiency and increasing the time exhaust gases spend inside where condensation can form.

In Grandview, winter temperatures that drop into the teens and twenties keep chimneys cold throughout the heating season. This extends condensation time during each furnace cycle. Exterior chimneys and those built along exterior walls stay colder longer, accelerating the deterioration process.

How Damage Develops Over Time

The damage can progress invisibly inside the chimney flue. Acidic moisture can dissolve mortar first, creating gaps between bricks and tiles. These gaps can allow combustion gases to escape into wall cavities, attics, and occupied rooms rather than venting safely outdoors.

As mortar deteriorates, the bricks and clay can shift, separate, or collapse.

The chimney can lose its ability to contain heat and support its own weight. Weakened walls can allow heat transfer to wooden framing members, creating fire risks. Carbon monoxide and other combustion gases can find escape routes through compromised mortar joints.

The visible symptoms often appear late in the deterioration timeline.

By the time homeowners notice problems, significant structural damage may have already occurred internally where inspection is difficult without specialized equipment.

Here are the most common questions homebuyers ask about unlined chimneys:

What does it mean if a chimney is unlined?

An unlined chimney lacks the protective sheet metal liner inside the masonry structure that safely channels combustion gases away from the masonry walls and sends it outdoors. This exposes bare brick, clay, and mortar to direct contact with exhaust gases.

Chimneys built before the 1940s often have no liner at all—just stacked brick or clay with mortar joints. The chimney forms a hollow vertical shaft from the basement to the roof. When a furnace (or gas water heater) vents into this open cavity, exhaust gases contact every brick, mortar joint, and masonry surface along the way.

This direct exposure can create multiple problems:

- The rough interior surface of stacked bricks disrupts smooth airflow, reducing draft efficiency. Poor draft means combustion gases don’t rise and exit as quickly as they should, increasing the time they spend inside the chimney where condensation can form.

- Unlined chimneys cannot prevent heat transfer to surrounding materials. In Grandview homes where chimneys run along exterior walls or through unheated attics, the temperature difference between hot exhaust and cold masonry creates ideal conditions for condensation. The acidic moisture can attack mortar over time.

- Deteriorating mortar joints in unlined chimneys can create pathways for gases to escape into wall cavities, attics, and living spaces. Unlike a lined chimney where gases stay contained within the metal liner, an unlined chimney has dozens of potential leak points wherever mortar has weakened.

Many older chimneys have clay tile liners instead of brick, but are still considered inadequately lined for modern gas furnaces. The clay provides better protection than nothing, but it still needs a metal liner insert to handle today’s cooler, wetter exhaust safely.

You can sometimes identify an unlined chimney by looking down from the roof. If you see rough brick or clay surfaces instead of metal pipe, the chimney lacks a liner.

Is it safe to use an unlined chimney?

Ask any chimney sweep and they’ll tell you that using an unlined chimney for any gas appliance is not recommended.

Unlined chimneys can allow acidic condensation to attack mortar directly, creating paths for carbon monoxide to leak into your home while weakening the chimney structure.

Chimneys need liners to contain combustion gases and protect masonry materials from heat and moisture damage.

Without a liner, exhaust gases contact bare brick and mortar surfaces that weren’t designed to handle direct exposure to acidic condensation. This is especially problematic in Grandview’s climate, where cold winter temperatures accelerate condensation rates.

Unlined chimneys built 70-100 years ago initially vented coal furnaces and later oil or gas equipment that ran much hotter than today’s systems.

Those older furnaces wasted 40-50% of their heat up the chimney, keeping the flue hot and dry. Modern efficient furnaces waste only 20% of their heat, which means cooler, moisture-laden exhaust.

When this moist exhaust enters an unlined chimney, condensation can form quickly on cold masonry surfaces.

The acidic moisture can dissolve mortar joints, creating gaps and channels through the chimney walls. These openings can provide escape routes for carbon monoxide, nitrogen dioxide, and other combustion gases.

There are structural risks that extend beyond gas leaks.

Deteriorating mortar can weaken the chimney’s ability to contain heat and support its own weight. Bricks can shift, separate, or collapse entirely.

In extreme cases, damaged chimneys have caused house fires when heat transferred through compromised walls to wooden framing members.

Many building codes prohibit venting gas appliances into unlined chimneys specifically because of these documented risks.

Even if the furnace appears to operate normally, the damage can progress hidden from view inside the chimney and homeowners should consider installing a properly sized metal liner before the damage becomes too great.

Does a clay chimney need to be lined?

Yes, clay chimneys need metal liners when venting modern gas appliances.

Clay tiles alone cannot withstand the acidic condensation that today’s efficient furnaces produce, which can attack mortar joints and deteriorate the chimney from inside.

Clay tile chimneys were designed for wood-burning fireplaces and older atmospheric furnaces that operated at 400-600°F.

Those high temperatures kept exhaust gases hot and dry as they rose through the flue.

Modern 80% efficiency gas furnaces produce exhaust around 300-400°F, which is cool enough to condense inside the chimney when it contacts cold masonry surfaces.

When combustion gases condense, they form acidic moisture that can eat through the lime-based mortar holding clay tiles together.

In Grandview, where winter temperatures keep chimneys cold for months, this condensation can happen during most heating cycles. Over time, the deteriorating mortar can allow tiles to shift, crack, and separate.

Even if the clay tiles appear intact from the outside, the damage occurs internally where you cannot see it.

Deteriorated mortar joints can create gaps that allow carbon monoxide and other combustion gases to escape into wall cavities and living spaces instead of venting safely outdoors.

A stainless steel liner installed inside the clay chimney creates a sealed pathway that’s sized correctly for the furnace’s exhaust volume.

The metal resists acidic condensation and maintains proper draft. Grandview homeowners should budget $900-$3,800 for professional liner installation, depending on chimney height and accessibility.

Building codes in most jurisdictions now require proper liners when installing or replacing gas appliances.

The International Fuel Gas Code specifically addresses this because unlined or clay-only chimneys create documented safety concerns with modern heating equipment.

Are clay-lined chimneys safe?

Clay-lined chimneys are safe for wood-burning fireplaces but not recommended for modern gas furnaces without an additional metal liner.

The cooler exhaust from today’s furnaces creates condensation that clay tiles cannot handle.

Clay tile liners work well in applications where exhaust temperatures stay consistently above 450°F.

Traditional wood fireplaces and old gravity furnaces produced this level of heat. The hot gases stayed in vapor form as they rose through the chimney, preventing moisture from forming on the clay surfaces.

Gas furnaces with 80% efficiency ratings extract more heat for your home, which means less heat goes up the chimney.

Exhaust temperatures of 300-400°F seem hot, but they’re cool enough to reach dewpoint when they contact cold chimney walls. This is especially problematic in Grandview during winter months when outdoor temperatures drop into the teens and twenties.

When exhaust condenses on clay tiles, the resulting moisture can contain sulfuric and carbonic acids from the combustion process.

These acids can dissolve the calcium carbonate in mortar joints and gradually eat away at the clay material itself. The deterioration accelerates in exterior chimneys or chimneys built along exterior walls because they stay colder longer.

But you won’t see this damage from the living space.

The destruction happens inside the chimney flue where mortar crumbles and tiles develop hairline cracks. These compromised areas can allow combustion gases to leak into wall cavities, attics, and occupied rooms. Carbon monoxide detectors may provide warning, but they’re the last line of defense.

Clay liners that served Grandview homes safely for decades can become problematic within 5-10 years of a furnace upgrade if homeowners don’t install a metal liner.

The clay itself isn’t defective—it’s simply being used in an application it wasn’t designed for.

Is a chimney flue liner necessary?

Yes, a chimney flue liner is necessary for gas furnaces.

Modern building codes require liners specifically because decades of research proved that unlined or inadequately lined chimneys create significant safety concerns.

The International Fuel Gas Code and International Residential Code both mandate properly sized metal liners for gas appliances. Local jurisdictions in the Kansas City metro area, including Grandview, enforce these requirements through permit and inspection processes.

Liners also serve three critical functions:

- They create a smooth, continuous pathway that’s sized correctly for your furnace’s exhaust volume. Proper sizing ensures gases rise and exit quickly without cooling too much inside the chimney.

- They contain all combustion byproducts within a sealed channel, preventing carbon monoxide and other combustion gases from leaking into your home.

- They protect masonry materials from heat, moisture, and acidic condensation damage.

Without a liner, you’re asking a brick or clay structure to perform functions it wasn’t designed for.

Masonry materials absorb moisture, allow gases to permeate through mortar joints, and deteriorate when exposed to acidic condensation. Grandview’s freeze-thaw cycles worsen this damage as absorbed moisture expands and contracts with temperature changes.

Stainless steel liners resist corrosion and typically last 15-20 years with proper maintenance.

Aluminum liners cost less but only work with certain furnace types and may last only 5 years. Professional installation ensures the liner connects properly to your furnace, maintains required clearances, and includes necessary components like rain caps and chimney top plates.

Skipping the liner installation might save $900-$3,800 initially, but the resulting chimney damage, potential carbon monoxide exposure, and reduction in property value create far greater expenses and risks.

The liner metal flue liner is essential safety equipment that protects both your home’s structure and your family’s health.

Finding gas furnaces venting into unlined chimneys isn’t uncommon in older Grandview homes.

The challenge is that these systems often appear to function normally, masking the progressive damage occurring inside the chimney where homeowners can’t see it.

The good news is that proper chimney liner installation addresses the safety risks while allowing homeowners to continue using their existing furnace.

Professional chimney contractors can assess the chimney’s condition, recommend the appropriate liner type, and complete installation typically within a day.

The investment in a chimney liner protects both immediate safety and long-term property value.

Documented liner installation demonstrates responsible maintenance that buyers and inspectors expect in older Grandview homes with gas heating systems.

About the Author

Steve Rodriguez is a professional home inspector and the owner of Bulldog Professional Inspection Services. He performs more than 600 home inspections annually all across the KC metro area.

Based in: Raymore, MO

Service Areas: Belton, Raymore, Harrisonville, Grandview, Lee’s Summit, Blue Springs, Raytown, Independence, Liberty, Kansas City, MO, Kansas City, KS, Olathe, Leawood, Overland Park, Prairie Village, Shawnee, Lenexa

Certifications: Certified Master Inspector® (CMI). International Association of Certified Home Inspectors (InterNACHI) Certified Professional Inspector since 2004.

This article is based on a real inspection conducted in December 2025. The property address has been excluded for privacy. Cost estimates reflect Kansas City metro area pricing as of December 2025 and may vary based on specific conditions and contractor selection.

Helpful Links

- Check out our GBP post about this lesson

- Recent inspections in Grandview, MO

- Home inspection lessons found in other Grandview, MO homes

- Learn more about your HVAC system in the Grandview area

Schedule Your Home Inspection

Call: (816) 564-3081

Email: info@bulldoginspect.com

Schedule Your Inspection Online